publications

publications by categories in reversed chronological order

2025

-

Implicit Modeling for 3D-printed Multi-material Computational Object Design via PythonCharles Wade, Devon Beck, and Robert MacCurdyProceedings of the 10th ACM Symposium on Computational Fabrication, 2025

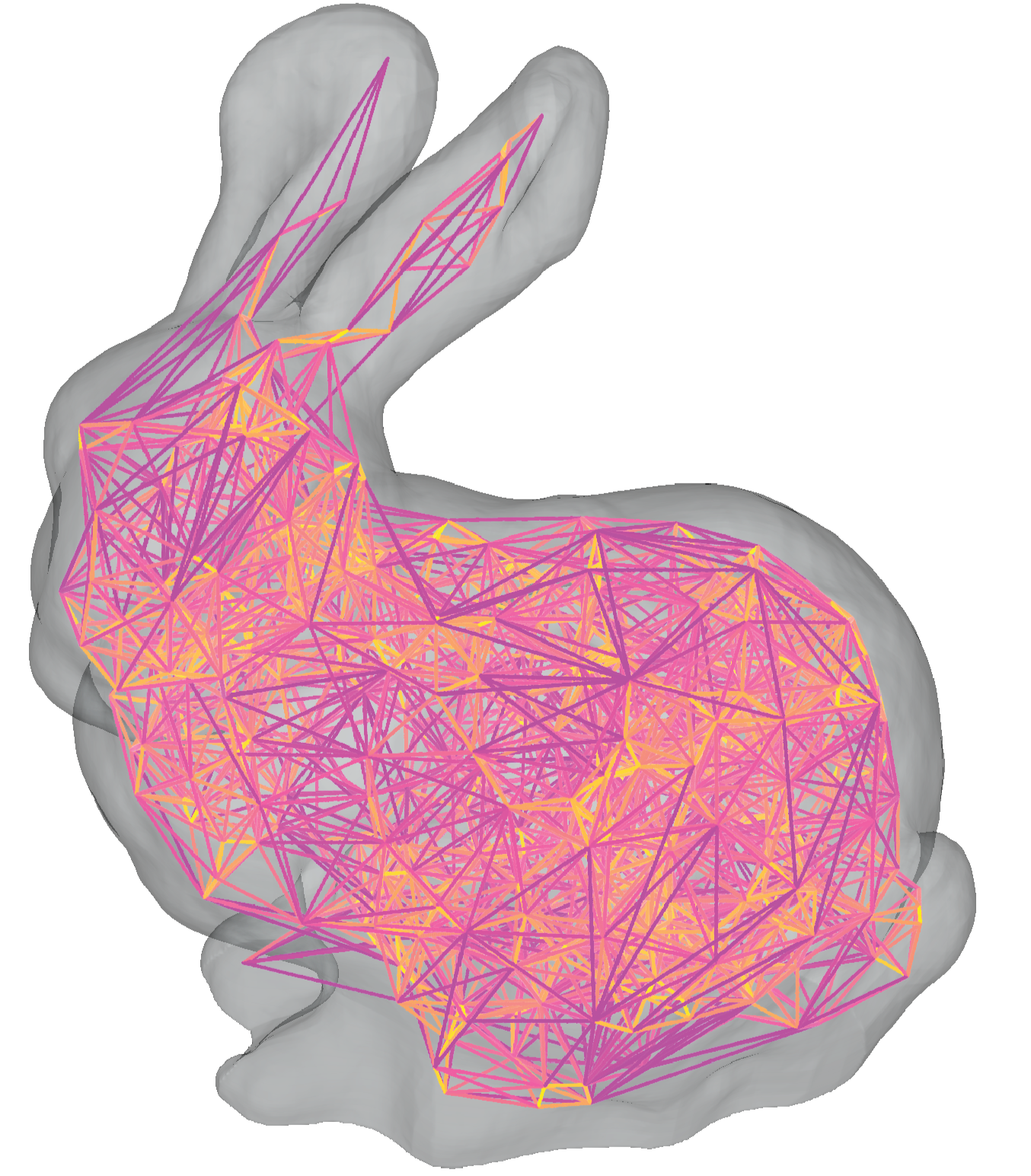

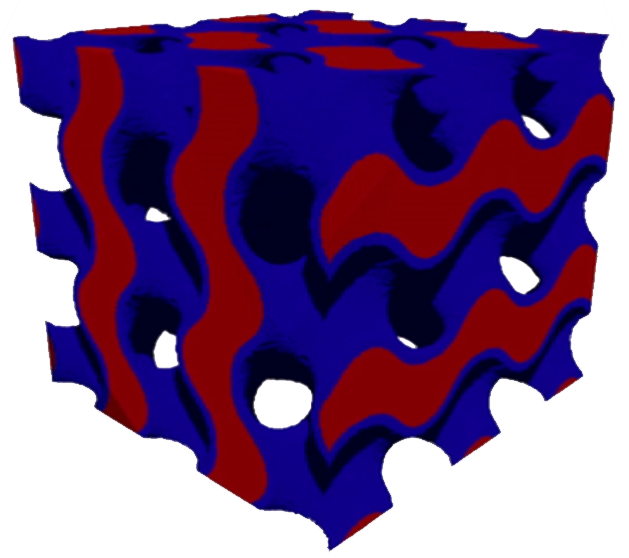

Implicit Modeling for 3D-printed Multi-material Computational Object Design via PythonCharles Wade, Devon Beck, and Robert MacCurdyProceedings of the 10th ACM Symposium on Computational Fabrication, 2025This paper introduces open-source contributions designed to accelerate research in volumetric multi-material additive manufacturing and metamaterial design. We present a flexible Python-based API facilitating parametric expression of multi-material gradients, integration with external libraries, multi-material lattice structure design, and interoperability with finite element modeling. Novel implicit multi-material modeling techniques enable detailed spatial grading at multiple scales within lattice structures. Additionally, our framework integrates with finite element analysis, offering predictive simulations via adaptive mesh sizing and direct import of simulation results to guide material distributions. Practical case studies illustrate the utility of these contributions, including functionally graded lattices, algorithmically generated structures, and simulation-informed designs, exemplified by a multi-material bicycle seat optimized for mechanical performance and rider comfort. Finally, we introduce a mesh export strategy compatible with standard slicing software, significantly broadening the accessibility and adoption of functionality graded computational design methodologies for multi-material fabrication.

@article{wade2025pyvcad, title = {Implicit Modeling for 3D-printed Multi-material Computational Object Design via Python}, author = {Wade, Charles and Beck, Devon and MacCurdy, Robert}, journal = {Proceedings of the 10th ACM Symposium on Computational Fabrication}, year = {2025}, doi = {https://doi.org/10.48550/arXiv.2509.15562}, } -

Implicit Toolpath Generation for Functionally Graded Additive Manufacturing via Gradient-Aware SlicingCharles Wade, Devon Beck, and Robert MacCurdyAdditive Manufacturing, 2025

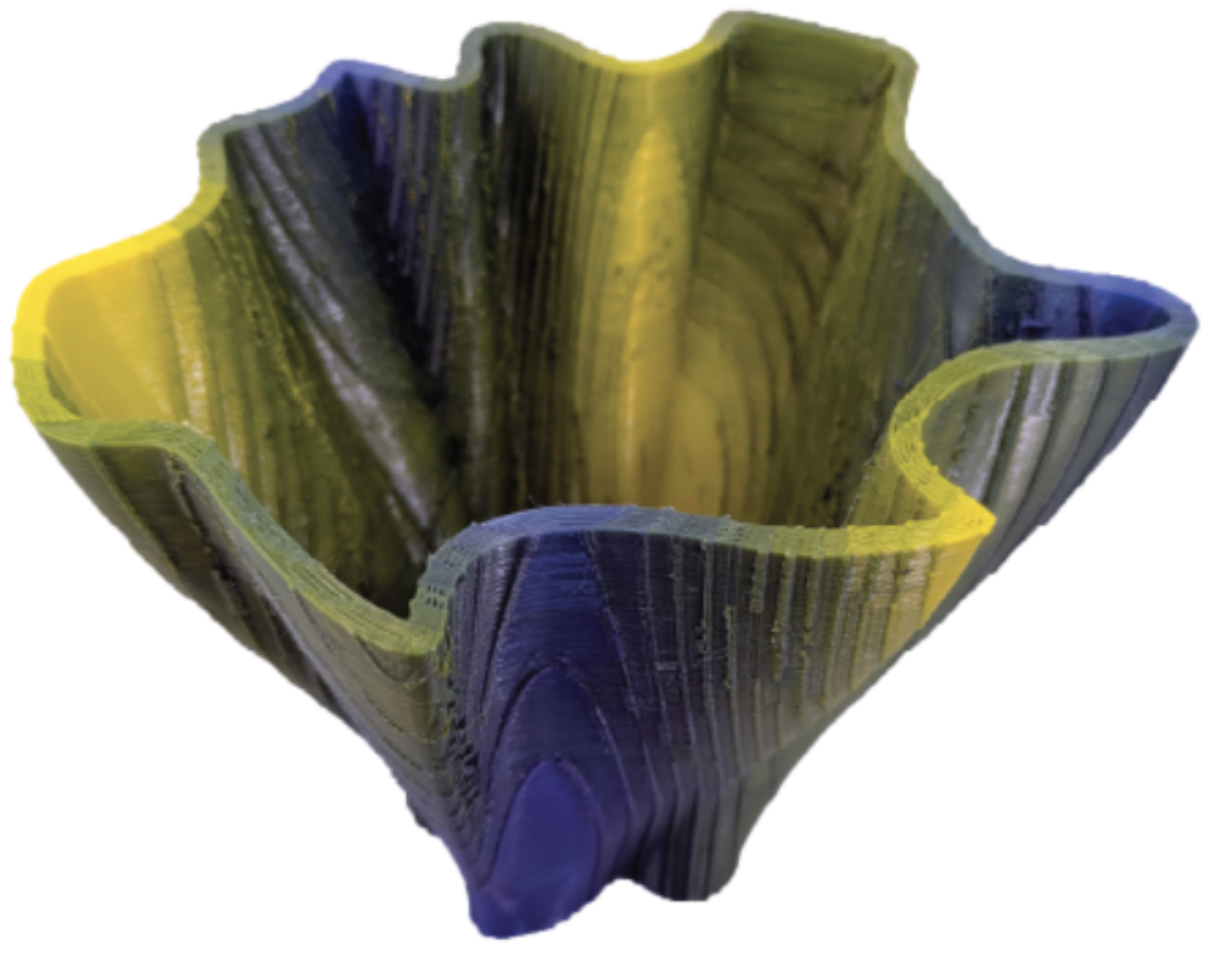

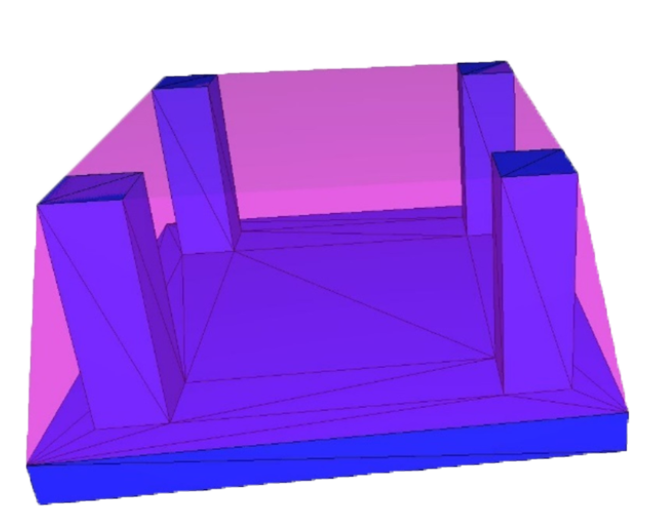

Implicit Toolpath Generation for Functionally Graded Additive Manufacturing via Gradient-Aware SlicingCharles Wade, Devon Beck, and Robert MacCurdyAdditive Manufacturing, 2025This paper presents a novel gradient-informed slicing method for functionally graded additive manufacturing (FGM) that overcomes the limitations of conventional toolpath planning approaches, which struggle to produce truly continuous gradients. By integrating multi-material gradients into the toolpath generation process, our method enables the fabrication of FGMs with complex gradients that vary seamlessly in any direction. We leverage OpenVCAD’s implicit representation of geometry and material fields to directly extract iso-contours, enabling accurate, controlled gradient toolpaths. Two novel strategies are introduced to integrate these gradients into the toolpath planning process. The first strategy maintains traditional perimeter, skin, and infill structures subdivided by mixture ratios, with automated ’zippering’ to mitigate stress concentrations. The second strategy fills iso-contoured regions densely, printing directly against gradients to eliminate purging and reduce waste. Both strategies accommodate gradually changing printing parameters, such as mixed filament ratios, toolhead switching, and variable nozzle temperatures for foaming materials. This capability allows for controlled variation of composition, density, and other properties within a single build, expanding the design space for functionally graded parts. Experimental results demonstrate the fabrication of high-quality FGMs with complex, multi-axis gradients, highlighting the versatility of our method. We showcase the successful implementation of both strategies on a range of geometries and material combinations, demonstrating the potential of our approach to produce intricate and functional FGMs. This work provides a robust, open-source, and automated framework for designing and fabricating advanced FGMs, accelerating research in multi-material additive manufacturing.

@article{wade2025implicit, title = {Implicit Toolpath Generation for Functionally Graded Additive Manufacturing via Gradient-Aware Slicing}, author = {Wade, Charles and Beck, Devon and MacCurdy, Robert}, journal = {Additive Manufacturing}, year = {2025}, doi = {https://doi.org/10.1016/j.addma.2025.104963}, } -

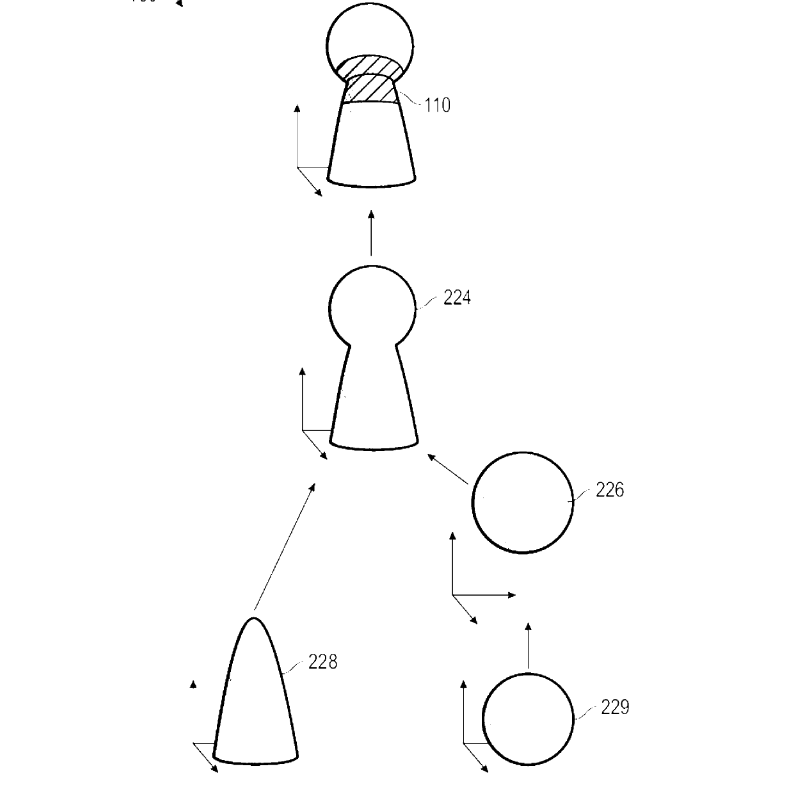

Multi-material volumetric modeling systems and methodsCharle Wade, and MacCurdy RobertJan 2025Patent Application WO2024238483A2

Multi-material volumetric modeling systems and methodsCharle Wade, and MacCurdy RobertJan 2025Patent Application WO2024238483A2@misc{Wade_MacCurdy_Multi-material_Modeling_2025, title = {Multi-material volumetric modeling systems and methods}, author = {Wade, Charle and Robert, MacCurdy}, year = {2025}, month = jan, note = {Patent Application WO2024238483A2}, url = {https://patents.google.com/patent/WO2024238483A2/}, }

2024

-

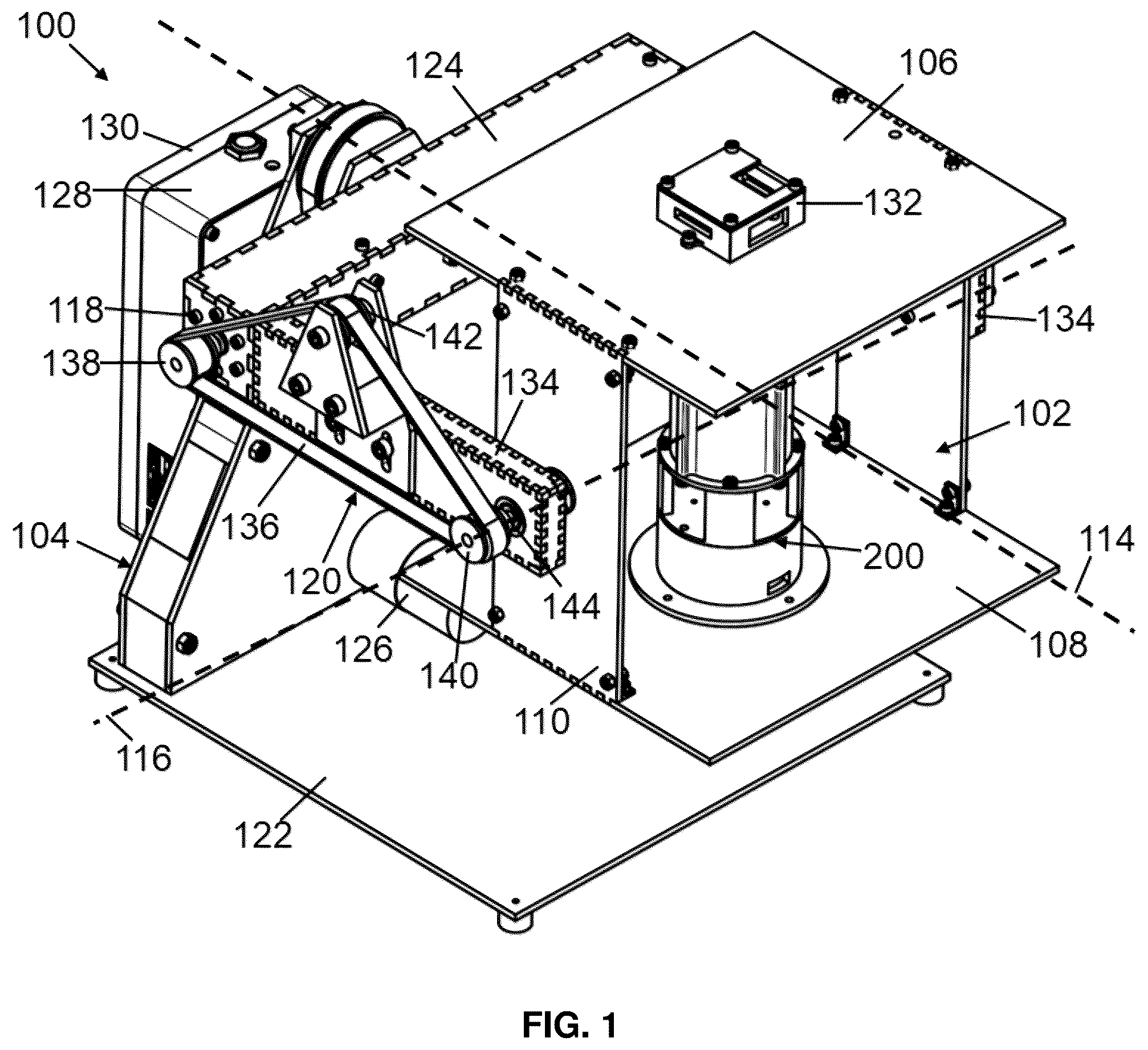

Adjustable gravity simulator for tissue and organ culturingEda Yildirim-Ayan, Halim Ayan, and Charles WadeJun 2024US Patent US20240200014A1

Adjustable gravity simulator for tissue and organ culturingEda Yildirim-Ayan, Halim Ayan, and Charles WadeJun 2024US Patent US20240200014A1@misc{Yildirim-Ayan_Ayan_Wade_2024, title = {Adjustable gravity simulator for tissue and organ culturing }, author = {Yildirim-Ayan, Eda and Ayan, Halim and Wade, Charles}, year = {2024}, month = jun, note = {US Patent US20240200014A1}, url = {https://patents.google.com/patent/US20240200014A1/}, } -

OpenVCAD: An open source volumetric multi-material geometry compilerCharles Wade, Graham Williams, Sean Connelly, Braden Kopec, and Robert MacCurdyAdditive Manufacturing, Jun 2024

OpenVCAD: An open source volumetric multi-material geometry compilerCharles Wade, Graham Williams, Sean Connelly, Braden Kopec, and Robert MacCurdyAdditive Manufacturing, Jun 2024Modern additive manufacturing has made significant advancements in multi-material fabrication techniques that allow for position-specific control of material deposition. With these advancements, design tools have fallen behind machine capabilities in specifying volumetric information. Traditionally, design and fabrication workflows have expressed multi-material objects as several single-material bodies. By storing only the information about the surfaces of the geometries, information about the volumetric composition of the solids is unrepresented. The intense interest in compliant mechanisms and meta-materials demands a new design method that can support architecting material distribution throughout an object. To address these needs, we present OpenVCAD, an open-source volumetric design compiler with multi-material capabilities. OpenVCAD provides a scriptable suite of geometric and material design methods that enable efficient representation of object with complex geometry and material distributions. OpenVCAD allows functional specification of multi-material volumes that are parameterized on spatial locations, yielding complex multi-material distributions that would be impossible to describe using alternative methods. This paper will present the OpenVCAD pipeline, compare it to related work, and demonstrate its use through the design and manufacturing of functionally graded multi-material components.

@article{OpenVCAD, title = {OpenVCAD: An open source volumetric multi-material geometry compiler}, journal = {Additive Manufacturing}, pages = {103912}, year = {2024}, issn = {2214-8604}, doi = {https://doi.org/10.1016/j.addma.2023.103912}, url = {https://www.sciencedirect.com/science/article/pii/S2214860423005250}, author = {Wade, Charles and Williams, Graham and Connelly, Sean and Kopec, Braden and MacCurdy, Robert}, keywords = {Volumetric design, Multi-material additive manufacturing, Meta-materials, Lattice-structures, InkJet 3D printing, Functional grading}, } -

ORNL Slicer 2 - Open Source CopyrightAlex Roschli, Michael Borish, Abigail Barnes, Charles Wade, Breanne Crockett, Liam White, Cameron Adkins, USDOE Office Energy Efficiency, and Renewable EnergyMay 2024

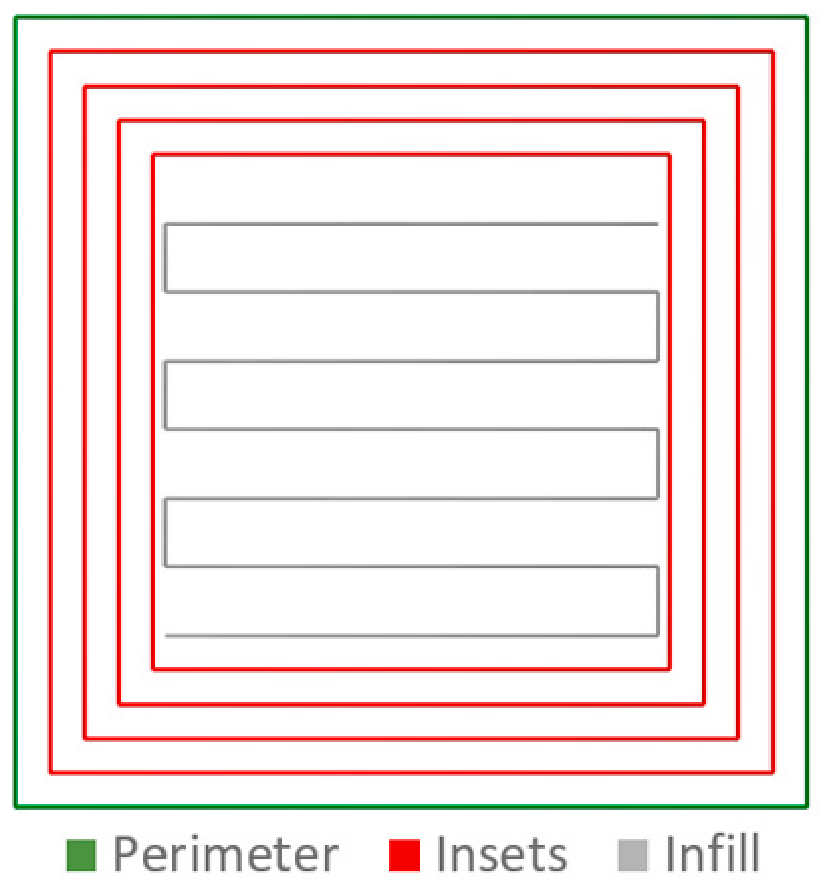

ORNL Slicer 2 - Open Source CopyrightAlex Roschli, Michael Borish, Abigail Barnes, Charles Wade, Breanne Crockett, Liam White, Cameron Adkins, USDOE Office Energy Efficiency, and Renewable EnergyMay 2024@misc{osti_2352739, title = {ORNL Slicer 2 - Open Source Copyright}, author = {Roschli, Alex and Borish, Michael and Barnes, Abigail and Wade, Charles and Crockett, Breanne and White, Liam and Adkins, Cameron and of Energy Efficiency, USDOE Office and Energy, Renewable}, abstractnote = {ORNL Slicer 2 is a slicing program for additive manufacturing. It takes a solid body mesh object, typically as .STL file, and converts that into machine readable instructions, called g-code, that a 3D printer can use to build the object. The functionality includes loading and positioning an object, slicing it into layers, fitting toolpaths to the layers, and outputting g-code to construct the object. All of this is contained within a graphical user interface (GUI) that allows the user to define all of the settings specific to their machine and process, then preview the resultant g-code before starting the printing process.}, url = {https://www.osti.gov/biblio/2352739}, doi = {10.11578/dc.20240520.1}, year = {2024}, month = may, }

2023

-

Determining Optimal Print Orientation Using GPU-Accelerated Convex Hull AnalysisCharles Wade, Breanne Crockett, Michael Borish, and Robert MaccurdyIn Proceedings of the 8th ACM Symposium on Computational Fabrication, May 2023

Determining Optimal Print Orientation Using GPU-Accelerated Convex Hull AnalysisCharles Wade, Breanne Crockett, Michael Borish, and Robert MaccurdyIn Proceedings of the 8th ACM Symposium on Computational Fabrication, May 2023In fused filament fabrication (FFF), the orientation of a part within the printer volume can dramatically affect print quality and probability of success. An object’s orientation determines how much support structure will be required and the strength of adhesion between the deposited material and the build surface. Selecting a part’s orientation is a non-trivial problem that users of FFF slicing software face routinely. Numerous part orientations need to be considered to find the best according to the results of the slicing process. This paper presents a method to automatically determine an optimal printing orientation for FFF that maximizes build-surface adhesion while minimizing the need for support structure. The algorithm considers the slicing angle and a configurable angle for overhang that requires supporting structure. By employing GPU acceleration and convex hull analysis to limit candidate orientations, the algorithm can run in real time as a preprocessing aid to users slicing parts.

@inproceedings{10.1145/3623263.3623360, author = {Wade, Charles and Crockett, Breanne and Borish, Michael and Maccurdy, Robert}, title = {Determining Optimal Print Orientation Using GPU-Accelerated Convex Hull Analysis}, year = {2023}, isbn = {9798400703195}, publisher = {Association for Computing Machinery}, address = {New York, NY, USA}, url = {https://doi.org/10.1145/3623263.3623360}, doi = {10.1145/3623263.3623360}, booktitle = {Proceedings of the 8th ACM Symposium on Computational Fabrication}, articleno = {4}, numpages = {9}, keywords = {additive manufacturing, GPU acceleration, toolpath-planning, optimization, computer-aided design}, location = {, New York City, NY, USA, }, series = {SCF '23}, } - Load balancing for multi-beam additive manufacturing systemsBenjamin C. Stump, Brian T. Gibson, Jay T. Reynolds, Charles Wade, Michael C. Borish, and Peter L. WangAdditive Manufacturing, May 2023

As powder bed fusion (PBF) additive manufacturing (AM) becomes a more mature field, system configurations are gradually moving away from the classic single heat source, layer-by-layer system configurations towards unconventional system configurations that offer higher throughput. Higher throughput systems allow PBF systems to be considered for a larger variety of industrial applications. However, the inclusion of multiple heat sources, or beams, also increases the complexity of the control schemes needed. For multi-beam systems with overlapping fields of view, the distribution of workload, or load balancing, across these beams directly affects the total print time for a build. Additionally, the probability of any beam failing in a multi-beam system increases with the number of beams. While manual methods of load balancing and dealing with beam failures are reasonable for current generation multi-beam systems, as system configurations become more complex, manual methods will become prohibitively inefficient. This paper introduces two different ways to load balance multi-beam systems of various configuration types, regardless of their complexity, which are highly performant. A consequence of this performance is the enablement of on-the-fly load balancing in the event a beam fails, thus improving system robustness.

@article{STUMP2023103708, title = {Load balancing for multi-beam additive manufacturing systems}, journal = {Additive Manufacturing}, pages = {103708}, year = {2023}, issn = {2214-8604}, doi = {https://doi.org/10.1016/j.addma.2023.103708}, url = {https://www.sciencedirect.com/science/article/pii/S2214860423003214}, author = {Stump, Benjamin C. and Gibson, Brian T. and Reynolds, Jay T. and Wade, Charles and Borish, Michael C. and Wang, Peter L.}, keywords = {Load balancing, Additive manufacturing, Optimization}, }

2022

-

Hybrid Curve Fitting for Reducing Motion Commands in Object ConstructionCharles Wade, and Michael BorishIn 2022 International Solid Freeform Fabrication Symposium, May 2022

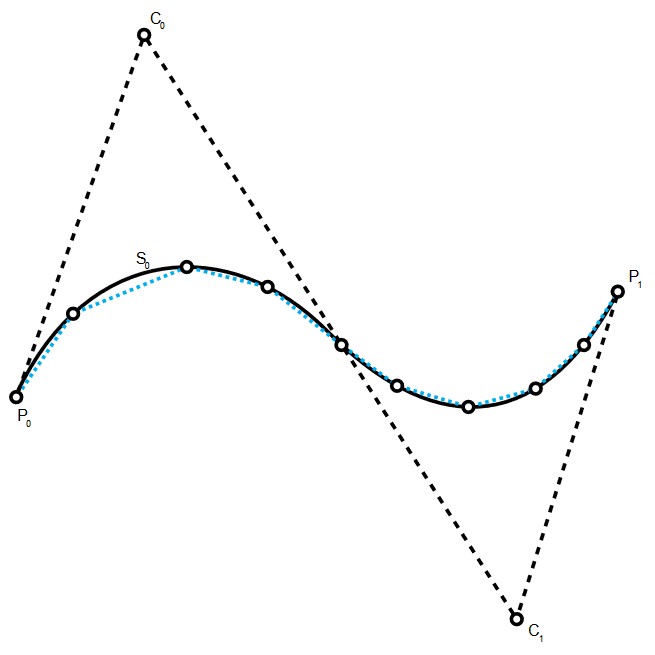

Hybrid Curve Fitting for Reducing Motion Commands in Object ConstructionCharles Wade, and Michael BorishIn 2022 International Solid Freeform Fabrication Symposium, May 2022@inproceedings{wade2022hybrid, title = {Hybrid Curve Fitting for Reducing Motion Commands in Object Construction}, author = {Wade, Charles and Borish, Michael}, booktitle = {2022 International Solid Freeform Fabrication Symposium}, year = {2022}, }

2021

-

A GPU-based Approach for Path Planning Optimization via Travel Length ReductionMichael Borish, and Charles WadeProcedia Manufacturing, May 2021

A GPU-based Approach for Path Planning Optimization via Travel Length ReductionMichael Borish, and Charles WadeProcedia Manufacturing, May 2021@article{borish2021gpu, title = {A GPU-based Approach for Path Planning Optimization via Travel Length Reduction}, author = {Borish, Michael and Wade, Charles}, journal = {Procedia Manufacturing}, volume = {53}, pages = {310--317}, year = {2021}, publisher = {Elsevier}, }

2019

-

Low Cost Remote Algae Detection Utilizing Embedded Hardware, Custom Sensors, and Additive ManufacturingCharles Wade, and Teran M. EricksenProceedings of The National Conference on Undergraduate Research, May 2019

Low Cost Remote Algae Detection Utilizing Embedded Hardware, Custom Sensors, and Additive ManufacturingCharles Wade, and Teran M. EricksenProceedings of The National Conference on Undergraduate Research, May 2019@article{wade2019low, title = {Low Cost Remote Algae Detection Utilizing Embedded Hardware, Custom Sensors, and Additive Manufacturing}, author = {Wade, Charles and Ericksen, Teran M.}, journal = {Proceedings of The National Conference on Undergraduate Research}, year = {2019}, }